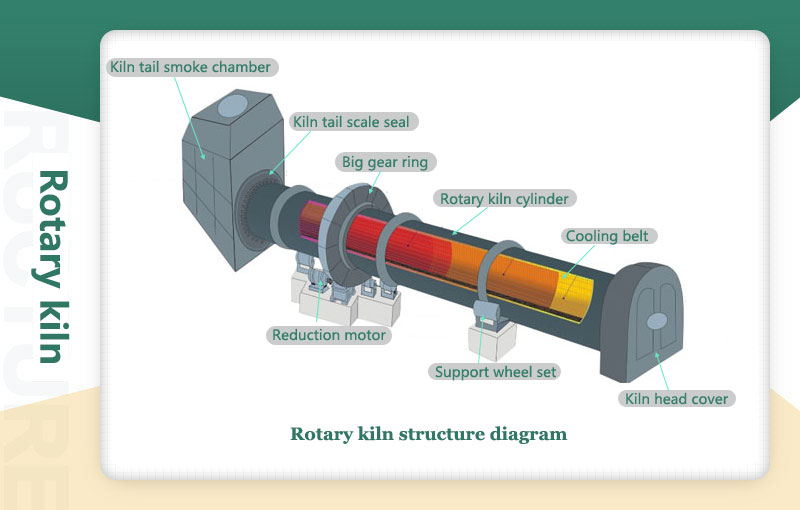

The rotary kiln is a large-scale thermal equipment that realizes continuous heat treatment of materials by rotating the cylinder. Its structure mainly consists of a cylinder, a support device, a transmission system, a sealing device and a combustion system. Its structure is a cylindrical cylinder placed at an angle, which slowly rotates to make the material roll inside, heat it and complete physical or chemical reactions. The equipment is widely used in mineral processing, metallurgy, chemical industry and other fields due to its simple structure, strong processing capacity and adaptability to a variety of materials.

The rotary kiln is a cylindrical equipment placed at an angle and rotating slowly, which realizes calcination, sintering and heat treatment of materials through rotation and high temperature treatment. Its working principle mainly includes the following core links:

1. Material feeding: The material enters the kiln from the high end of the rotary kiln through the feed port, and continuous feeding is usually achieved with the help of a conveyor belt or a feeder.

2. Rotation and movement: The kiln body is installed at an inclination of 3%-5%, and is driven by a drive device to rotate slowly (usually at a speed of 3-6 rpm). The material is subjected to the combined effects of friction and gravity in the cylinder: the particles are lifted to a certain height by the kiln wall, and then slide down, forming periodic tumbling and axial movement. This movement causes the material to be continuously mixed and evenly heated in the kiln, and gradually moves from the high end to the low end.

3. Heat exchange and reaction: The combustion device sprays fuel at the kiln head to generate high-temperature flames and hot air, which conduct thermal radiation and convection heat exchange with the material. The material undergoes physical and chemical reactions at high temperatures, such as water evaporation, organic combustion, carbonate decomposition, mineral sintering, etc., and is eventually converted into the desired product.

4. Waste gas treatment and cooling: The waste gas generated during the calcination process is discharged through the exhaust pipe and can be discharged or recycled after treatment. The treated material is discharged at the end of the kiln and quickly cooled by the cooling device for subsequent processing or storage.

5. Control system: Modern rotary kilns are equipped with an automated control system to monitor parameters such as temperature, pressure, and speed in real time to optimize operating efficiency and ensure product quality.

The rotary kiln is widely used in many industrial fields due to its high efficiency, continuous operation and strong adaptability:

Cement production: One of the core equipment, used to calcine raw materials (limestone, clay, etc.) to produce cement clinker, which is a key link in cement manufacturing.

Metallurgical industry: Processing iron ore, extracting metals (such as iron, zinc, aluminum, etc.) or removing harmful substances (such as sulfur and phosphorus) through high-temperature magnetization or reduction reaction. Roasting auxiliary materials such as active lime and ceramsite sand.

Chemical industry: Pyrolysis and catalytic reaction of organic matter. High-temperature harmless treatment of hazardous waste.

Building materials and environmental protection field: Drying and sintering various building materials. Processing solid waste for resource utilization.

Mineral processing industry: Magnetization roasting of lean iron ore to enhance the magnetism of ore and improve magnetic separation efficiency.

The rotary kiln achieves uniform heating and reaction of materials through rotational motion, combined with high-temperature combustion and precision control, and has become an indispensable industrial equipment in many industries. The optimization of its structural design and working principle not only improves production efficiency, but also provides technical support for energy conservation and environmental protection, playing an important role in modern industrial production.