As an important screening equipment in industrial production, the stable operation of the vibrating screen is crucial to production efficiency and product quality. However, in actual operation, the problem of uneven feeding of the vibrating screen is often ignored, but it may trigger a series of chain reactions, from equipment loss to safety hazards, and its impact cannot be underestimated. New Gaonai Heavy Industry will deeply explore the causes, consequences and systematic solutions of uneven feeding of the vibrating screen.

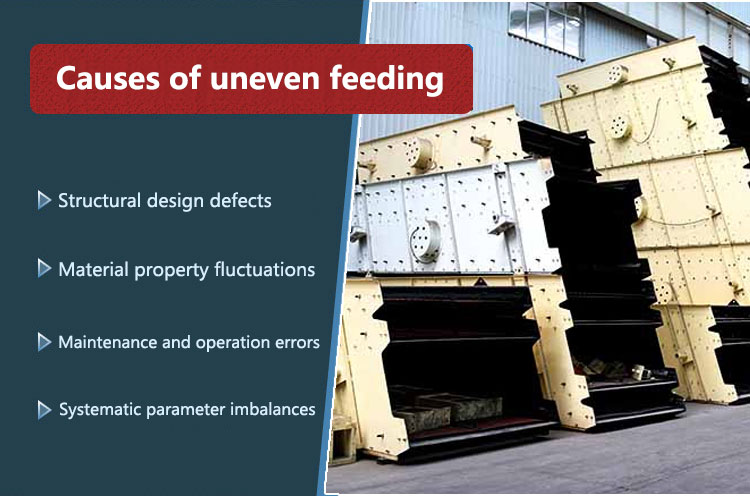

The root causes of uneven feeding of the vibrating screen usually involve many factors such as equipment, operation, material characteristics and maintenance, which can be summarized as follows:

1. Defects in feeding equipment and structural design

Irrational design or abnormal operation of the feeder, such as belt deviation and funnel accumulation, result in the inability to evenly distribute the material to the screen surface. The distance between the feed inlet and the screen surface is too high, and the impact force of the material falling is too large, causing the local screen surface to be overloaded and the other side to be empty.

2. Fluctuation of material characteristics

Uneven distribution of material particle size, excessive humidity or sticky substances blocking the screen, resulting in obstructed flow and inability to spread evenly. The feed volume fluctuates, exceeding the equipment’s processing capacity, causing the screen surface load to be unbalanced.

3. Equipment maintenance and operation errors

Damage to the screen, insufficient tension or improper installation lead to abnormal material diversion. Inconsistent angles of the vibrator eccentric blocks, differences in spring stiffness or bearing damage cause the screen body to vibrate in a disordered direction, and the material cannot move along the expected path.

4. Systematic parameter imbalance

The vibration frequency and amplitude settings do not match the material characteristics, resulting in abnormal material throwing trajectories, uneven accumulation or dispersion.

The impact of uneven feeding of the vibrating screen is not isolated, and its consequences often present a “domino effect”:

1. Equipment loss and safety hazards

Local screen surface overload aggravates screen wear and shortens service life; long-term partial load operation may cause cracking of the screen structure, loosening of fasteners, and even overturning of the screen). Springs, bearings and other components are accelerated by fatigue damage due to uneven force, increasing maintenance costs.

2. Decreased screening efficiency and quality

The material accumulation area is not screened thoroughly, and the fine material is mixed with the coarse material, resulting in reduced classification accuracy; the unloaded area wastes screening capacity and the overall processing volume decreases.

3. Increased energy consumption and operating costs

When the equipment operates under abnormal vibration conditions, the energy consumption increases significantly; frequent shutdowns for maintenance also affect the continuity of the production line and reduce corporate benefits.

Solving the problem of uneven feeding of vibrating screens requires coordinated advancement from three dimensions: technology, management and maintenance:

1. Technical optimization and equipment improvement

Feeding system upgrade: Use variable frequency feeders to achieve quantitative and uniform feeding, or add distributors to the hopper to dynamically adjust material distribution.

Screen structure optimization: Adjust the height and angle of the feed inlet to reduce material impact; select wear-resistant screens and replace them regularly to ensure the tension of the screen surface.

Intelligent monitoring and control: Install an online monitoring system to detect the screen surface load and vibration parameters in real time, and adjust the feeding speed or vibration frequency in a linked manner to avoid resonance and eccentric loading.

2. Operational specifications and training

Develop standardized operating procedures: clarify the feeding rate and screening parameter setting range of different materials, and strictly prohibit overload operation.

Train operators to identify signs of abnormal vibration, noise, etc., and intervene in time (such as cleaning the blockage and adjusting the angle of the eccentric block).

3. Preventive maintenance system

Regular inspections: Check the integrity of the screen and the consistency of the spring stiffness every week, and calibrate the angle of the vibrator eccentric block every month to ensure the stability of the equipment dynamic parameters.

Lubrication management: Maintain bearings and transmission parts on a periodic basis to prevent abnormal vibration caused by friction.

Environmental adaptability: For materials with high humidity or viscosity, add a screen cleaning device or pretreatment process (such as drying) to reduce the risk of blockage.

4. Industry differentiation strategy

It is allowed to appropriately relax the feeding uniformity requirements, but the structural strength of the screen body needs to be strengthened; strictly implement closed-loop feeding control, combined with high-precision monitoring, to ensure zero-deviation feeding.

The uneven feeding of the vibrating screen may seem like a small deviation, but it actually affects the stability and safety of the entire production chain. Through the organic combination of technological innovation, standardized operation, preventive maintenance and industry adaptation strategies, enterprises can avoid potential risks, tap into equipment efficiency and achieve long-term sustainable production. Only by integrating the concept of “uniform feeding” throughout the entire life cycle of the equipment can we lay a solid foundation for efficient screening.