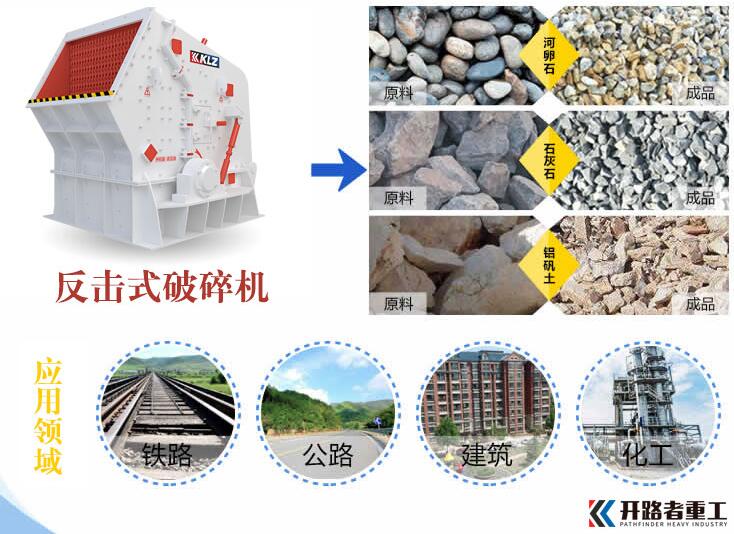

Impact crushers, essential crushing equipment in industries like mining, building materials, and cement, are subject to long-term, high-intensity operation and can develop various malfunctions due to wear, operating errors, or inadequate maintenance. Pioneer Heavy Industry has carefully summarized seven common impact crusher malfunctions and their solutions to help users quickly resolve them and ensure efficient equipment operation.