Introduction

Double Toothed Roll Crusher

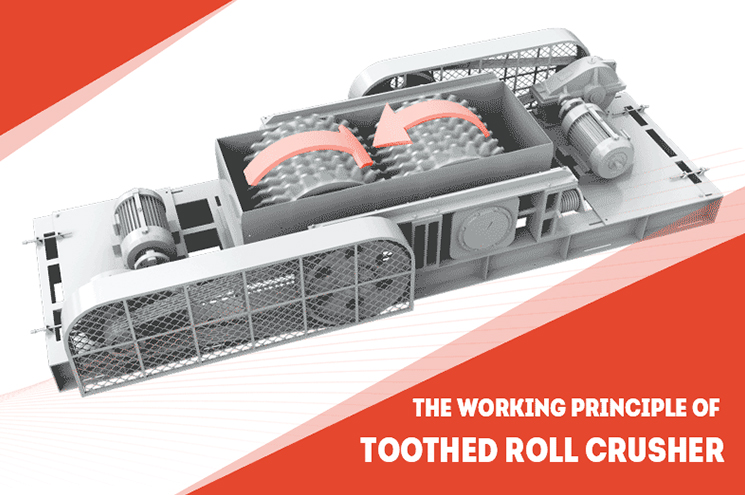

The Double Toothed Roll Crusher is a high-performance crushing equipment engineered for coarse and medium crushing of brittle and soft materials. It utilizes two counter-rotating rollers equipped with large, wear-resistant teeth that engage, shear, and crush the incoming material. This configuration provides a powerful breaking force and exceptional size reduction ratio while minimizing the generation of fines.

Designed for applications in coal preparation, metallurgy, chemical processing, cement plants, and power generation, the crusher excels in handling wet, sticky, or high-moisture materials that are difficult to process with conventional crushers. The adjustable roller gap allows users to control the output size, while the integrated spring or hydraulic overload protection system prevents equipment damage from uncrushable materials.

The Double Toothed Roll Crusher stands out for its compact design, low noise operation, high throughput, and ease of maintenance. With a reinforced structure and optimized tooth profile, it ensures long service life and consistent performance, making it an efficient and reliable solution for primary or secondary crushing tasks in demanding environments.