Introduction

Apron Feeder

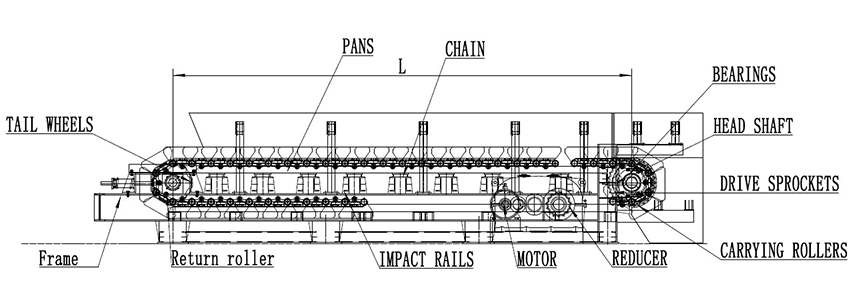

Apron Feeder is an industrial-grade material feeding machine built for continuous handling of coarse, abrasive, or high-temperature materials. It consists of a series of overlapping steel plates (aprons) attached to a heavy-duty chain system, forming a robust conveying platform. The feeder is driven by a powerful motor and gearbox, ensuring precise control of feed rate and torque.

The design of Apron Feeder allows it to operate under extreme conditions where conventional vibrating or belt feeders may fail. It is capable of handling large rocks, hot clinker, wet clay, or sharp-edged ores without degradation. The feeder is typically installed below hoppers, bins, or stockpiles, regulating material discharge to downstream equipment such as jaw crushers, impact crushers, or belt conveyors.

With adjustable speed and discharge control, Apron Feeder ensures consistent flow and prevents overloading. It offers advantages like shock resistance, low maintenance frequency, long service life, and ease of installation. It is a reliable solution for primary feeding applications in mining, aggregates, cement, steel, and bulk material handling sectors.